SOP - Production Gelcoat Repair

SOP - Production Gelcoat Repair

• For blending and polishing sprayed-on gelcoat repairs.

To customize your SOP, click the color coded box to choose the

Good/Better/Best/Unique product for each step.

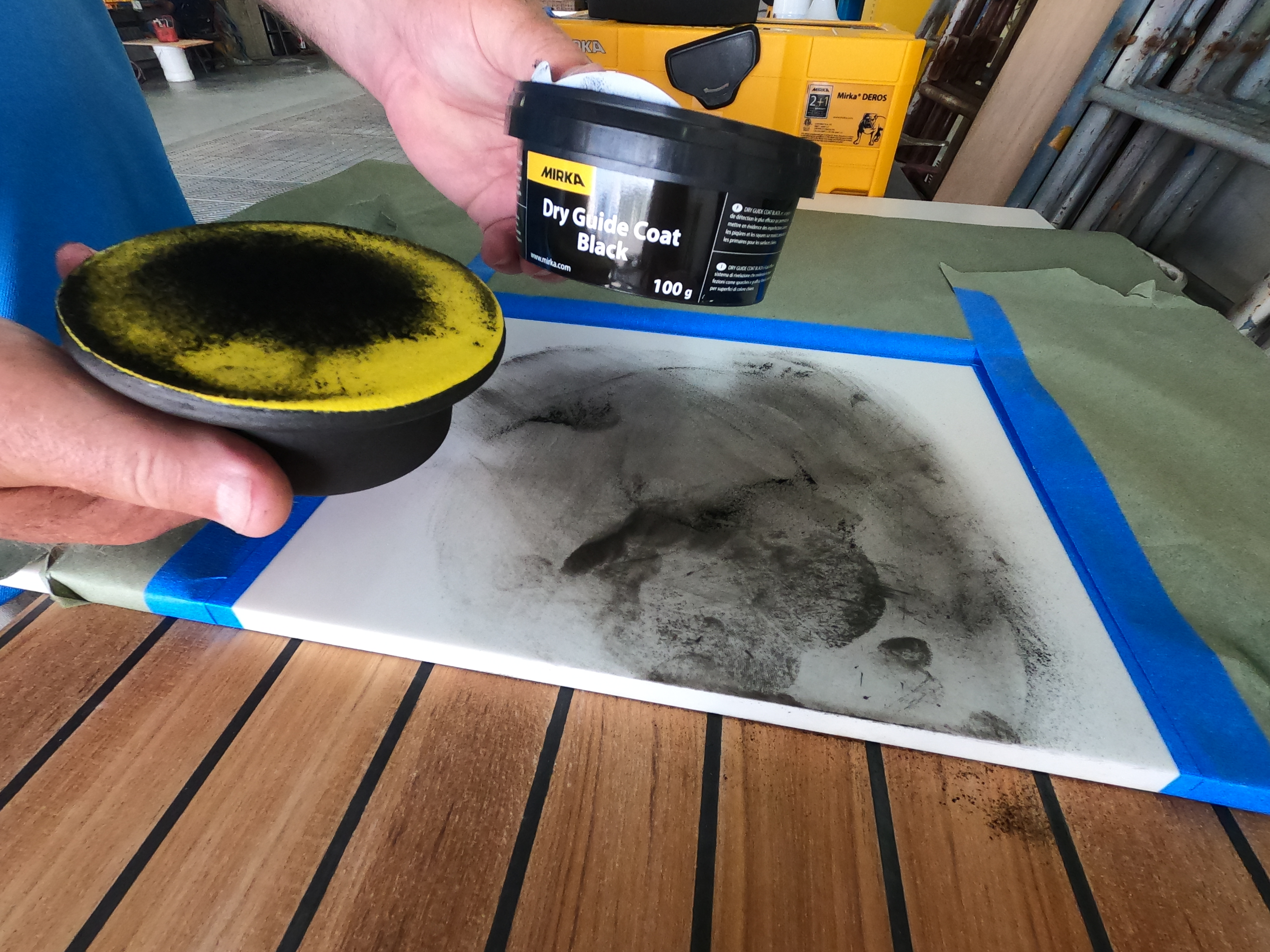

Dry Guide Coat

9193500111 (Black)

9193600111 (White)

Or Dykem Layout Fluid

Soap and Water or

Wax and Grease Remover

Using a suitable cleaner, properly clean the surface to remove dirt, wax, grease or any other contaminants from the gelcoat.

Use a highlighter such as Guide Coat #9193500111 to show high spots when sanding.

The highlighter will be removed during the sanding process and show any surface defects that need to be repaired or removed.

Novastar Film P400, P600, P800

FG-6MH-400 / 600 /800

5": MRP-550CV

915GV28 Backup Pad

6": MRP-650CV

916GV48 Backup Pad

Gold Multi-Fit Film P400, P600, P800

Coming SOON!

5": MRP-550CV

915GV28 Backup Pad

6": MRP-650CV

916GV48 Backup Pad

Sand surface using P400, P600 or P800 grit abrasive, depending on the size of repair. Wipe surface clean using a

microfiber cloth.

Polishing Compound 45

PC45-1L

MPADTW-7.5

(7" Rotary Buffer)

Buff using PC45 compound in conjunction with a twisted wool pad (MPADTW-7.5)

Use a slow speed (1,500 rpm) to prevent

"burning" the finish.

Keep the pad clean from compound build-up.

Polishing Compound 10

PC10-1L

MPADBF-8

(7" Rotary Buffer)

Polish using PC10 with a black foam pad (MPADBF-8).

Use a slow speed (1,500 rpm) to prevent “burning” the finish.

*Note: If a foam pad is not being used, a yellow polishing pad could be substituted.